At Xometry, we offer a wide range of CNC machining capabilities to ensure your custom parts are manufactured exactly as intended. While our expert machinists often select the most efficient machining method for your design, we understand you may have a preference based on historical project needs or specific part characteristics.

This guide provides a quick reference to the most common CNC sub-processes, which are the specific techniques, machines, and setups used to subtractively manufacture your parts. Reviewing these options will help you understand and inform your selection on our quoting menu.

No Preference

This is the default selection. This option allows the facility best suited to manufacture your part (whether they specialize in Milling, Turning, Mill-Turn, etc.) to use their core competencies to produce the part.

Best Suited For:

- Customers who are unsure which sub-process is best for their part.

- Projects where manufacturing flexibility is permissible.

- Parts that can be effectively produced using multiple different CNC sub-processes.

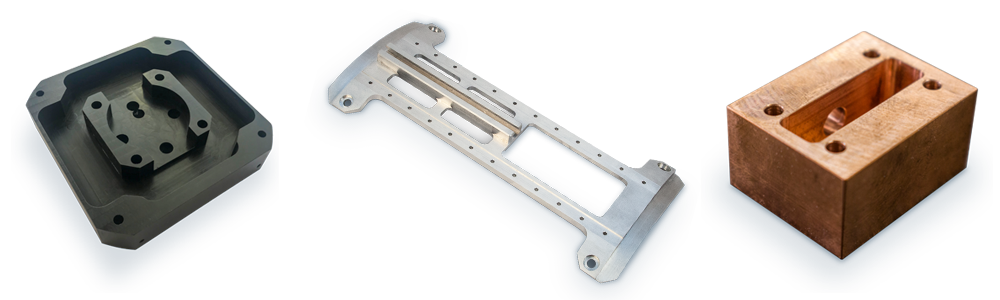

CNC Milling

CNC Milling uses a rotating cutting tool, such as an endmill, to remove material from a stationary workpiece. The cutting tool moves along multiple axes (typically 3, 4, or 5-axis) to create complex shapes, features, and contours.

Best Suited For:

- Complex parts that require features on multiple faces, such as pockets, slots, holes, and intricate surface contours.

- Prismatic parts (block-like shapes).

- Parts where internal or external cylindrical (turned) features are not the dominant characteristic.

CNC Turning

CNC Turning involves mounting the workpiece in a chuck and spinning it rapidly while a stationary cutting tool is fed into the part's circumference. Material is removed to create cylindrical features. This is often done using a CNC lathe.

Best Suited For:

- Parts with rotational symmetry, such as shafts, pins, bushings, fasteners, and simple cylindrical profiles.

- Threaded cylindrical components where the thread runs along the central axis (e.g., bolts, screws, threaded rods).

- Quick production of round components.

CNC Mill and Turning Combo

Also known as CNC Mill-Turn, this sub-process applies to parts that require a significant combination of rotational (turned) features and non-rotational (milled) features. While these parts can be efficiently machined on single, multi-tasking machines with live tooling, they may also be produced by transferring the part between separate CNC turning and CNC milling setups. Selecting this option highlights that the part requires both types of subtractive machining to be completed.

Best Suited For:

- Complex parts that require both turning (cylindrical features) and milling (non-symmetrical features like flats, cross-holes, and pockets) on the same component.

- Complex shafts or spindles that require both round bodies (turned) and features like keyways, gear teeth, or cross-holes (milled).

- Parts requiring off-axis features (e.g., holes drilled perpendicular to the main cylindrical body).

- Components with flats or hex features milled onto a round body (e.g., wrench flats on a custom bolt head).

Swiss Type Turning

A specialized turning method where the bar stock slides through a guide bushing while the cutting tool remains stationary. Because the material is supported right at the point of the cut, it eliminates the vibration and deflection common in standard turning.

Best Suited For:

- Long, slender parts with high length-to-diameter ratios, such as needle valves, long pins, or shafts.

- High-volume production of small, intricate components (typically with diameters under 1.25").

- Complex medical components (like bone screws) or electronic contacts that require high precision and fine surface finishes.

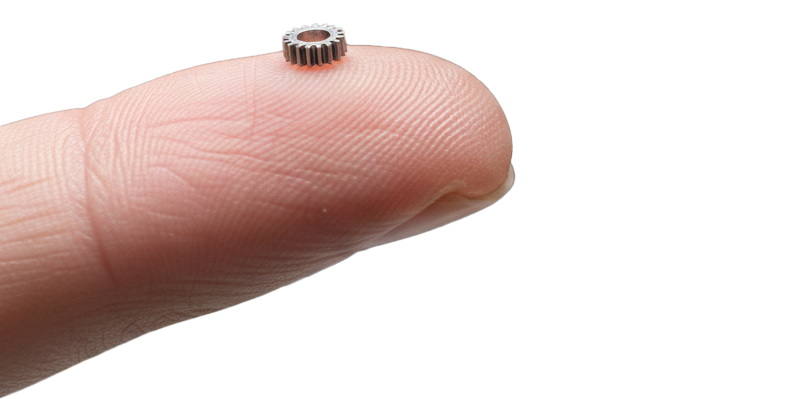

Micro Machining

Micro Machining refers to manufacturing parts or features with dimensions in the micrometer range (e.g., typically <1 mm). This process uses extremely small tools and high-precision, high-speed spindles on specialized machines to achieve micron-level tolerances.

Best Suited For:

- Tiny parts required in medical, aerospace, and electronics industries, such as surgical instruments, standoffs, and fuel injectors.

- Micro-gears for small-scale mechanical systems, such as those found in watches and small motors.

- Parts with sub-millimeter features and tolerances tighter than ±0.001".

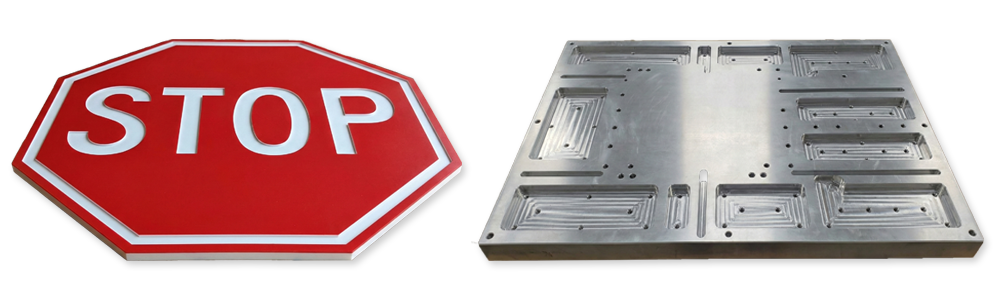

CNC Routing

CNC Routing is a high-efficiency subtractive process using large, gantry-style machines optimized for cutting parts from sheet materials. Unlike milling, which often involves facing the material to achieve a specific thickness, routing is designed to preserve the original top and bottom surfaces of the stock material. The machine cuts only the necessary features, such as outlines, pockets, and holes, allowing for significantly faster run times and lower costs. This method is ideal for industrial applications where the stock material's factory finish and thickness meet the requirements of your final part.

Best Suited For:

- Cost-effective industrial components where the top and bottom surfaces do not need machining (e.g., aluminum tooling plates, fixture bases, and brackets).

- Optically clear panels (e.g., Acrylic/Polycarbonate windows) where preserving the factory face is critical to maintain transparency without the need for post-polishing.

- Multi-layer material applications, such as routed signs made from ColorCore® or similar HDPE, where precise depth control reveals contrasting internal colors.

- Large, flat parts that require simple features (pockets, holes, profiles) and would be cost-prohibitive to produce on a standard CNC mill.

Learn more about our CNC machining services:

CNC Machining Service Page

Xometry Materials

CNC Design Guide